Whether you’re designing a luxury rigid box or a folded brochure, how your paper folds matters more than you think. Two common techniques used in the print and packaging world, creasing and grooving, may sound similar, but they serve very different purposes.

In this article, we’re diving into the world of creasing vs grooving. We’ll explain how each works, when to use them, and why understanding the difference can make or break your next printing project.

Table of Contents

ToggleWhat Is Creasing?

How Creasing Works

Best Materials for Creasing

Where Creasing Is Used

You’ve probably seen creasing in action on:

Greeting cards

Brochures and menus

Folded cartons

Flyers with multiple panels

What Is Grooving?

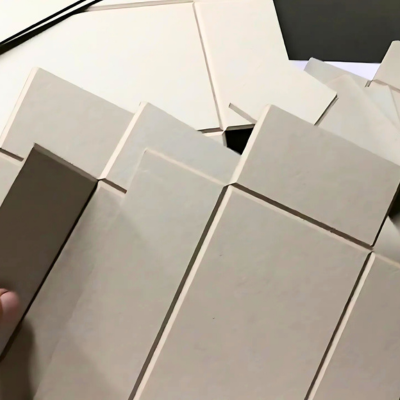

How Grooving Works

Best Materials for Grooving

Where Grooving Is Used

You’ll find grooving on:

Rigid luxury boxes

Premium presentation boxes

Book covers

Product display kits

It’s the secret sauce behind many high-end packaging projects, particularly in the cosmetics, electronics, and gift sectors.

Key Differences Between Creasing and Grooving

| Feature | Die Creasing | Grooving |

|---|---|---|

| Process | Pressed indentation | V-shaped cut removal |

| Material | Thin paper/cardstock | Thick board (greyboard, kappa board) |

| Purpose | Fold guidance | Clean rigid folding |

| Used In | Flyers, cards, menus | Luxury boxes, rigid kits |

| Tools Used | Creasing rule and counter die | Grooving blades |

| Fold Apperance | Subtle ridge | Sharp, crisp angle |

Why This Matters in Packaging Design?

If you’re working with a printer or packaging supplier, knowing the difference between creasing and grooving helps avoid costly errors. Here’s how:

Structural Integrity: Using creasing on a rigid box board will lead to cracking. Using grooving on thin paper is unnecessary and expensive.

Finish Quality: Grooved boxes look sleek and seamless. Creased items look elegant when folded cleanly.

Production Efficiency: Printers choose techniques based on equipment, material, and finishing goals. Understanding both helps you set better expectations.

When to Choose Creasing or Grooving (and Vice Versa)

Still not sure what to choose? Here’s a general rule of thumb:

If your material is below 350 gsm, go with creasing.

If it’s a rigid board, grooving is the way to go.

If you’re making luxury boxes, grooving is non-negotiable.

For marketing prints or folding leaflets, creasing is perfect.

How Veesham Helps You Decide

Whether you’re a designer, marketer, or business owner getting print work done, understanding the difference between creasing vs grooving helps you make smarter decisions. The right technique enhances the final look, protects your material, and elevates the product experience.

At Veesham Printing Press, we’ve helped thousands of brands find the perfect fold—be it subtle creases on a brochure or crisp grooves on a rigid box. Contact us today to start your printing.